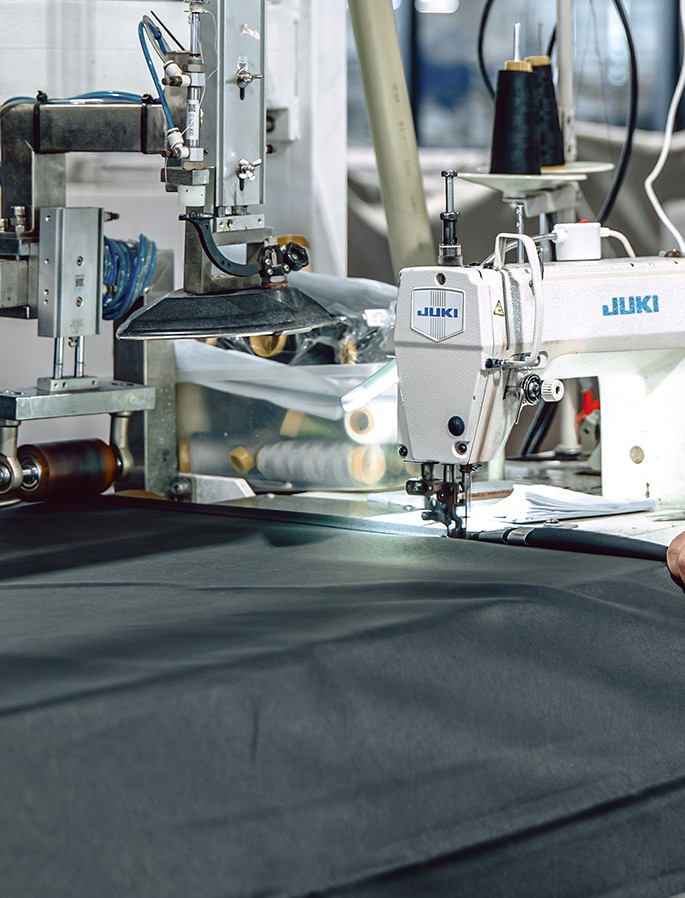

Production process

From fabric cutting to finished product production, we adhere to the spirit of craftsmanship that strives for excellence, and every process is strictly controlled. This reflects our pursuit of quality and emphasis on details.

Fabric development

Fabric inspection

Roll the side edge

Cropping

base

overlay

finalize the design

Tie the knot

test article

package

needle inspection

Bottom